Emergency towing arrangements

2022-12-04 12:25

Introduction

The emergency towing arrangements should be so designed as to facilitate salvage and emergency towing operations on tankers primarily to reduce the risk of pollution. The arrangements should at all times be capable of rapid deployment in the absence of main power on the ship to be towed and easy connection to the towing vessel.

Application

Emergency towing arrangements shall be fitted at both ends on board every tanker of not less than 20,000 tones deadweight.

- For tankers constructed on or after 1 July 2002:

- The arrangements shall, at all times, be capable of rapid deployment in the absence of main power on the ship to be towed and easy connection to the towing ship. At least one of the emergency towing arrangements shall be pre-rigged ready for rapid deployment; and

- Emergency towing arrangements at both ends shall be of adequate strength taking into account the size and deadweight of the ship, and the expected forces during bad weather conditions. The design and construction and prototype testing of emergency towing arrangements shall be approved by the Administration, based on the Guidelines developed by the Organization.

- For tankers constructed before 1 July 2002:

- the design and construction of emergency towing arrangements shall be approved by the Administration, based on the Guidelines developed by the Organization

Actions required to the arrangements installed before 1 January 1996

The existing towing arrangements forward of the ship may be retained subject to a statement certifying of being approved in accordance with Res. A. 535(13).

Towing Components

The following table shows an overview of towing equipment and its requirements:

Strength of the towing components

All mentioned components listed in the above table must meet the strength requirements based on the following items:

- For tankers of 20,000 DWT and over but less than 50,000 DWT: working strength of at least 1,000 kN (type test load: 2,000 kN)

- For tankers of 50,000 DWT and over: working strength of at least 2,000 kN

(type test load: 4,000 kN)

The strength should be sufficient for all relevant angles of towline, i.e. up to 90° from the ship’s centerline to port and starboard and 30° vertical downwards. Other components should have a working strength sufficient to withstand the load to which such components may be subjected during the towing operation.

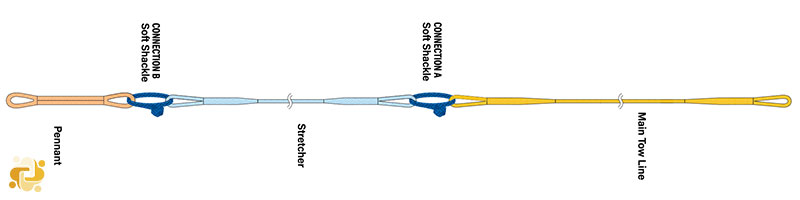

Towing Pennant and Connection

Pennants are used to avoid excessive wear on the main towline or stretcher and provide ease of handling for the tanker’s crew. Pennants are fitted with a large, soft eye at the free end, which makes it easier for the tanker’s crew to handle and provides safer connection and disconnection of the tow.

Because the towing pennant is made fast on board the assisted tanker through a fairlead, it is more likely to suffer from wear and mechanical damage than other components. Pennants are easily replaced and there should be a replacement strategy in place.

In general, wire pennants should be selected for wire towlines and synthetic pennants should be selected for synthetic towlines. This will avoid a reduction in strength due to induced twisting.

The towing pennant should have a hard eye-formed termination allowing connection to a standard bow shackle.

- Length of towing pennant: The towing pennant should have a length of at least twice the lightest seagoing ballast freeboard at the fairlead plus 50 m.

Strongpoint

The inboard end fastening should be a stopper or bracket or another fitting of equivalent strength. The strongpoint can be designed to be integral with the fairlead.

Where a windlass is used as the strong point, it should be constructed to give warning of undue strains by stalling at well below the designed maximum safe working load of the weakest element in the system. It should also be correctly sighted to minimize the need for complex line placement and utilize a dedicated fairlead for the emergency towing lines.

Chafing Gear and Fairleads

There are many types of chafing gear that can be used. Fairleads and ropes can have chafing pieces attached to stop contact rubbing and these will be in place on the vessel. Chafing chains may also be used and will be integrated into the system.

- Size: Fairleads should have an opening large enough to pass the largest portion of the chafing gear, towing pennant or towing line.

- Geometry: The fairlead should give adequate support for the towing pennant during towing operation which means bending 90°to port and to starboard side and 30°vertical downwards. The vending ratio (towing pennant bearing surface diameter to towing pennant diameter should be not less than 7 to 1.)

- Vertical location: The fairlead should be located as close as possible to the deck and, in any case, in such a position that the chafing chain is approximately parallel to the deck when it is under strain between the strongpoint and the fairlead.

Chafing Chain: Different solutions on design of chafing gear can be used. If a chafing chain is to be used, it should have the following characteristics:

- Type: The chafing chain should be stud link chain.

- Length: The chafing chain should be long enough to ensure that the towing pennant remains outside the fairlead during the towing operation. A chain extending from the strongpoint to a point at least 3 m beyond the fairlead should meet this criterion.

- Connecting limits: One end of the chafing chain should be suitable for connection to the strongpoint. The other end should be fitted with a standard pear-shaped open link allowing connection to a standard bow shackle.

- Stowage: The chafing chain should be stowed in such a way that it can be rapidly connected to the strongpoint.

READY AVAILABILITY OF TOWING ARRANGEMENTS

To facilitate approval of such equipment and to ensure rapid deployment, emergency towing arrangements should comply with the following criteria:

- The aft emergency towing arrangement should be pre-rigged and be capable of being deployed in a controlled manner in harbor conditions in not more than 15 min.

- The pick-up gear for the aft towing pennant should be designed at least for manual operation by one person taking into account the absence of power and the potential for adverse environmental conditions that may prevail during such emergency towing operations. The pick-up gear should be protected against the weather and other adverse conditions that may prevail.

- The forward emergency towing arrangement should be capable of being deployed in harbor conditions in not more than 1 h.

- The forward emergency towing arrangement should be designed at least with a means of securing a towline to the chafing gear using a suitably positioned pedestal toller to facilitate connection of the towing pennant.

- Forward emergency towing arrangements which comply with the requirements for aft emergency towing arrangements may be accepted.

- All emergency towing arrangements should be clearly marked to facilitate safe and effective use even in darkness and poor visibility.

- All emergency towing components should be inspected by ship personnel at regular intervals and maintained in good working order.