Immersion Suit

2022-07-26 10:52

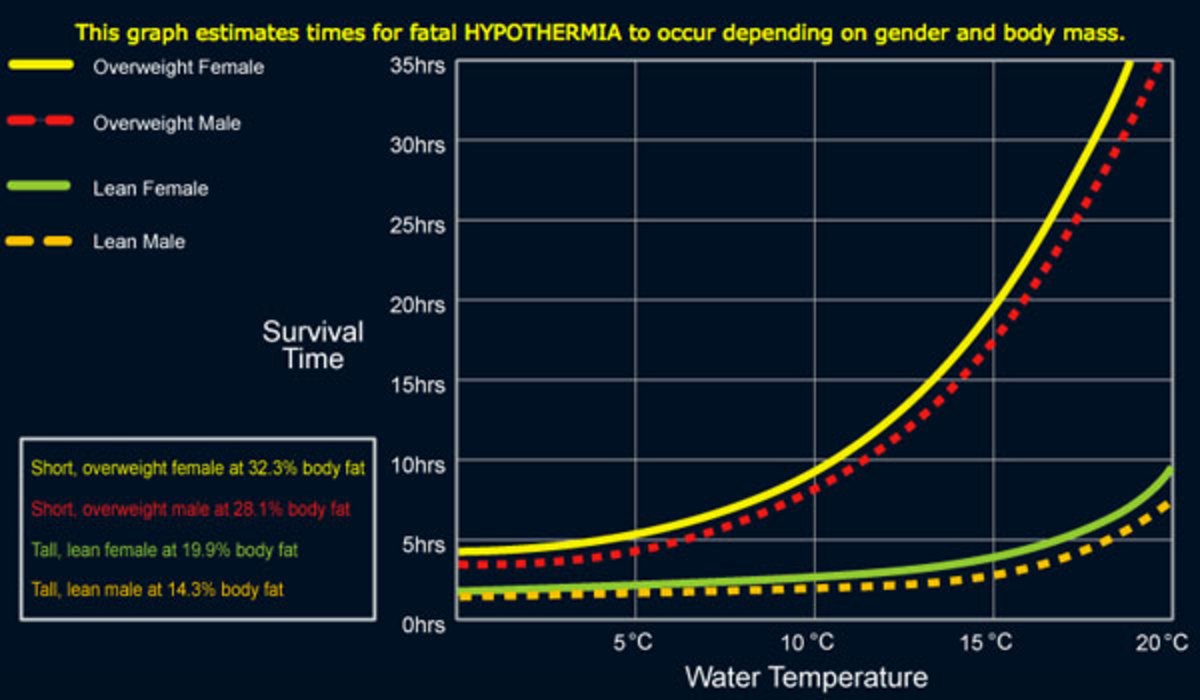

The sea has always been a hostile environment and the decision to live and work upon it takes courage, skill, determination and good training. Occasionally, things do go wrong and in extreme event ship's crew may have to abandon their vessel and that could lead to person being immersed in water which could be very cold water. Under most conditions, the body maintains a healthy temperature. When more heat is lost than your body can generate, hypothermia can result.

Hypothermia is a dangerous drop in body temperature below 35C (normal body temperature is around 37C). It's a medical emergency that needs to be treated in hospital.

Hypothermia may develop within minutes of being exposed to cold weather conditions or it may take several hours depending on the water and wind temperatures.

Wearing the immersion suit could make all the difference - the difference between life and death.

Hypothermia is a condition that is triggered when your body' temperature drops by just two degrees Celsius grade. As this happens, the body tries to protect itself. Circulation concentrates blood flow around the central part of the body and away from the arms and legs.

A person will start to shiver and then shake. This is the body attempting to heat itself up by muscular activity. As the Introduction to the Immersion Suits - 2 temperature drops another couple of degrees, this muscular activity starts to fail. In northern latitudes, when the waters are colder, this can happen in just fifteen minutes to an unprotected person. By that time you will lose muscular control and start to lose the ability to think patiently - this could be irreversible and result in death.

This situation need not arise if you know how an immersion suit works and are able to get into it correctly. It is very clever piece of kit that needs to be looked after. The suit is a one-piece item that is stored in a bag for easy access.

Take it out of the bag and lay it on a clean dry surface. Immersion suits are usually made of neoprene to provide thermal protection; they have special seals to stop water getting in and around the face and hands. The most important seal is the zip. To be able to use your hands most suits have the rubber or neoprene five finger gloves with anti-slip built in. They do not allow water to get in. In order to conserve heat, over mittens are supplied which fit over the rubber gloves to give greater insulation to the hands. Every bit of heat that can be saved is vital for survival.

Feet are just as important. Insulated boots are built in and will provide a non-slip footing. To assist with walking,

The mask protects the face from wind and water, helping the wearer to breath and preventing water from being swallowed. Behind the mask is the insulated head covering - this helps to reduce heat loss.

Over the top are reflective strips for high visibility to aid rescuer. It is important to obtain correct size of immersion suit so that the face wrapper will seal properly around the face. The worst thing that can happen is the water to get in and the body temperature start to drop. The zip is the most critical part of the suit. It is designed and manufacturer to an approved military standard and must be properly maintained. The zip must be fully closed so that the total seal is achieved and the suit becomes waterproof. There is a certain amount of resistance to the zip which is normal, and it is advised to practice opening and closing it.

Attached to the sleeve is a body line - it pulls out and can be attached through a loop to another person's suit. Rescuers can spot a group of people in the water much more easily than an individual. Make sure the whistle can easily be found - this is essential for attracting attention.

Immersion suit’s Regulation (SOLAS 2006 Amend / Chapter III / Reg. 7.3)

Immersion suits and anti-exposure suits:

An immersion suit, complying with the requirements of section 2.3 of the Code or an anti-exposure suit complying with section 2.4 of the Code, of an appropriate size, shall be provided for every person assigned to crew the rescue boat or assigned to the marine evacuation system party. If the ship is constantly engaged in warm climates* where, in the opinion of the Administration thermal protection is unnecessary, this protective clothing need not be carried.

General requirements for immersion suits

An immersion suit shall be constructed with waterproof materials such that:

- it can be unpacked and donned without assistance within 2 min, taking into account donning of any associated clothing*, donning of a lifejacket if the immersion suit must be worn in conjunction with a lifejacket to meet the requirements of paragraph 2.3.1.2, and inflation of orally inflatable chambers if fitted;

- it will not sustain burning or continue melting after being totally enveloped in a fire for a period of 2 s;

- it will cover the whole body with the exception of the face, except that covering for the hands may be provided by separate gloves which shall be permanently attached to the suit;

- it is provided with arrangements to minimize or reduce free air in the legs of the suit; and

- Following a jump from a height of not less than 4.5 m into the water there is no undue ingress of water into the suit.

An immersion suit on its own, or worn in conjunction with a lifejacket if necessary, shall have sufficient buoyancy and stability in calm fresh water to:

- lift the mouth of an exhausted or unconscious person clear of the water by not less than 120 mm; and

- Allow the wearer to turn from a face-down to a face-up position in not more than 5 s.

An immersion suit shall permit the person wearing it, and also wearing a lifejacket if the immersion suit is to be worn in conjunction with a lifejacket, to:

- climb up and down a vertical ladder at least 5 m in length;

- perform normal duties associated with abandonment;

- jump from a height of not less than 4.5 m into the water without damaging or dislodging the immersion suit or its attachments, or being injured; and

- swim a short distance through the water and board a survival craft.

An immersion suit which has buoyancy and is designed to be worn without a lifejacket shall be fitted with a light complying with the requirements of paragraph 2.2.3 and the whistle prescribed by paragraph 2.2.1.14.

An immersion suit which has buoyancy and is designed to be worn without a lifejacket shall be provided with a releasable buoyant line or other means to secure it to a suit worn by another person in the water.

An immersion suit which has buoyancy and is designed to be worn without a lifejacket shall be provided with a suitable means to allow a rescuer to lift the wearer from the water into a survival craft or rescue boat.

If an immersion suit is to be worn in conjunction with a lifejacket, the lifejacket shall be worn over the immersion suit. Persons wearing such an immersion suit shall be able to don a lifejacket without assistance. The immersion suit shall be marked to indicate that it must be worn in conjunction with a compatible lifejacket.

An immersion suit shall have buoyancy which is not reduced by more than 5% after 24 h submersion in fresh water and does not depend on the use of loose granulated materials.

PERIODIC TESTING OF IMMERSION SUIT

Research performed by several Member Governments has demonstrated that the seams and closures of immersion suits and anti-exposure suits experience deterioration over time. The rate and severity of deterioration may vary widely, depending upon the specific components and procedures employed in the manufacture of the suit and the conditions under which the suit is stored. However, even under ideal conditions, the materials and adhesives used have a finite service life and will inevitably experience a reduction in strength and/or loss of water tightness with age.

The Guidelines for monthly shipboard inspection of immersion suits and anti-exposure suits (MSC/Circ.1047) are very helpful in identifying obvious problems with a suit, but do not adequately address deterioration of seams and closures (zippers, etc.) which may not be readily apparent by visual inspection. Such deterioration can be detected by pressurization of the suit with air, and testing of the seams and closures for leaks with a soapy water solution.

To ensure the maintenance of adequate strength and water tightness of seams and closures of immersion suits and anti-exposure suits with age, it is recommended that each suit be subjected to an air pressure test such as the following, at intervals not exceeding three years, or more frequently for suits over ten years of age:

- A suitable head piece, fitted with a means to inject air into the suit, should be inserted into the face orifice of the suit and secured so as to minimize leakage around the face seal. A low-pressure monitoring device, either integral to the fitting for air injection or as a separate device, should also be inserted. If the suit is fitted with detachable gloves and/or boots, the wrists and/or cuffs should be sealed by inserting a short length of suitable diameter plastic pipe and securing the gloves and/or boots with suitable wire ties or hose clamps. The zipper should be fully zipped, and any face flap closed. The suit should then be inflated to a pressure of 0.7 to 1.4 kPa (0.1 to 0.2 psi). If an auxiliary inflatable means of buoyancy is provided, it should be inflated through the oral valve to a pressure of 0.7 kPa (0.1 psi) or until firm to the touch.

- Each seam and closure of the suit - and each seam, oral tube and attachment points and joint or valve of any auxiliary inflatable means of buoyancy - should then be covered with a soapy water solution containing enough soap to produce bubbles (if leakage is noted at a foot valve to the extent that air pressure cannot be maintained, the valves should be sealed for the test).

- If leaks are revealed by the propagation of bubbles at seams or closures, the leaking areas should be marked and, after cleaning the suit thoroughly with fresh water and drying it, repaired in accordance with the suit manufacturer's recommendations.

It is recommended that the air pressure test be performed at a suitable shore-based facility equipped to make any necessary repairs in accordance with the manufacturer's recommendations. In view of the wide variety of materials and adhesives used in immersion suits and anti-exposure suits, it is strongly recommended that any repairs to a suit be carried out by a facility which has access to the original manufacturer's recommended servicing instructions, parts and adhesives, and suitably trained personnel. The air pressure test may be carried out on board ship if suitable equipment is available.