Oil Mist Detector

Oil Mist Detector

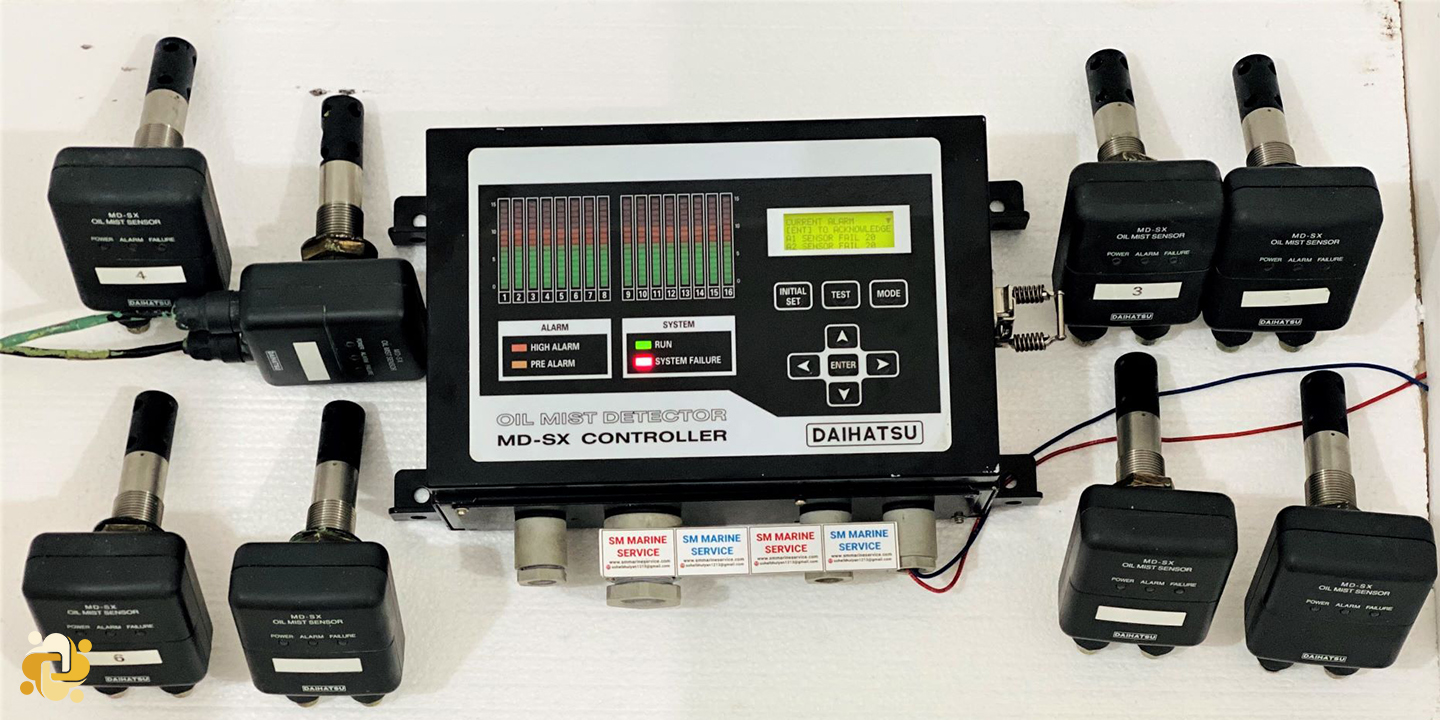

A device that measures the oil mist concentration by inserting an oil mist detector into the crankcase of a marine engine. The sensor converts the measured mist concentration into an electronic signal and sends it to the monitor. If the mist concentration exceeds a certain value, an alarm will be issued.

What is crankcase explosion?

It is an explosion that occurs in the crankcase because of the mixture of oil mist and air in the ratio that is within the range of flammability.

In addition, there must be a source of high temperature energy sufficient to initiate combustion. This source is called hot spot.

Why oil mist detector is fitted?

It is fitted to detect the oil mist concentration in the crankcase and to give early warning. To prevent the primary explosion. Alarm setting is 2.5% of the lower flammable limit.

Crankcase Oil Mist Detector Working (Photo-electric Type)

It basically comprises two parallel tubes of similar size, each having a photo-electric cell (these are light sensitive and generate an electric current which is proportional to the intensity of the light falling on their surface) fitted at one end. The lenses seal the tubes but allow light to pass.

Two identical beams of light from the centrally positioned same lamp, are reflected by mirrors to pass along the tubes on to the cells.

One of the tubes contains clean air and is called the reference tube. The other tube has connections through which the vapors of the crankcase are drawn by means of an electrically-driven extractor fan.

Sampling points are normally fitted to each cylinder crankcase and their connections are led to a rotating-selector-valve, which repeatedly connects each sampling point to the measuring tube, in proper sequence.

If the concentration of the oil-mist is present in a certain sample, light shall be obscured before reaching the cell of the measuring tube, the electrical balance will be disturbed and an alarm will be operated.

At the detection point, the rotator stops to indicate, which sampling point is to be investigated. After testing, the samples are led away to the atmosphere.

Note: The detector must be reset before the alarm ceases and then the sampling procedure will resume its cyclic monitoring.

Oil mist detection arrangements of crankcase requirement

Following engines are to be provided with oil mist detection arrangements (or engine bearing temperature monitors or equivalent devices) obtained type approval.

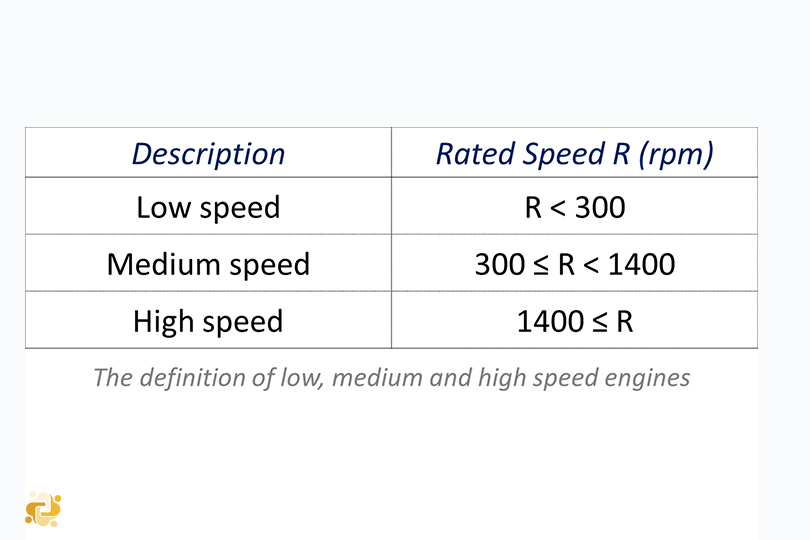

- Low speed diesel engines of 2,250 kW and above or having cylinders of more than 300 mm bore: alarm and slow down purposes.

- Medium and high speed diesel engines of 2,250 kW and above or having cylinders of more than 300 mm bore: alarm and automatic shutoff purposes.

The definition of low, medium and high speed engines

The oil mist detection arrangements are to be installed in accordance with the engine designer's

and oil mist manufacturer's instructions and recommendations.

The engine designer's and oil mist manufacturer's instructions are to be included the following particulars.

- Schematic layout of engine oil mist detection and alarm system showing location of engine crankcase sample points and piping or cable arrangements together with pipe dimensions to detector.

- Evidence of study to justify the selected location of sample points and sample extraction rate (if applicable) in consideration of the crankcase arrangements and geometry and the predicted crankcase atmosphere where oil mist can accumulate.

- The manufacturer's maintenance and test manual. (A copy of the manual is to be provided on board ship.)

Oil mist detection and alarm information is to be capable of being read from a safe location away from the engine.

Each engine is to be provided with its own independent oil mist detection arrangements and a dedicated alarm.

What are oil mist detector maintenance?

- Daily check alarm system.

- Check for any abnormal alarms in the panel.

- Detector head cleaning.

- Make sure fans is working.

It is important to carry out routine maintenance of OMD to prevent false alarms. The sensitivity of OMD should be checked on a regular basis. As all the samples contain a small amount of mist, the lenses and mirrors tend to get dirty and thus require periodic cleaning. The extractor fan and the rotating valve should be checked to avoid chocking of a particular sampling tube. The sampling tubes that connect cylinders to the OMD should not have any loops and also shouldn’t be of length more than 12.5 meters.

How will you take action when oil mist detector alarm is on?

- Inform to chief engineer

- Inform bridge, take the permission to stop the engine

- Gradually reduce the engine and then stop.

- Cool down the engine.

- Check the inside parts of the crankcase inspection.

- Make necessary repair

- Reset OMD and start engine

Type Testing Procedure for Crankcase Oil Mist Detection and Alarm Equipment Can be Found Here